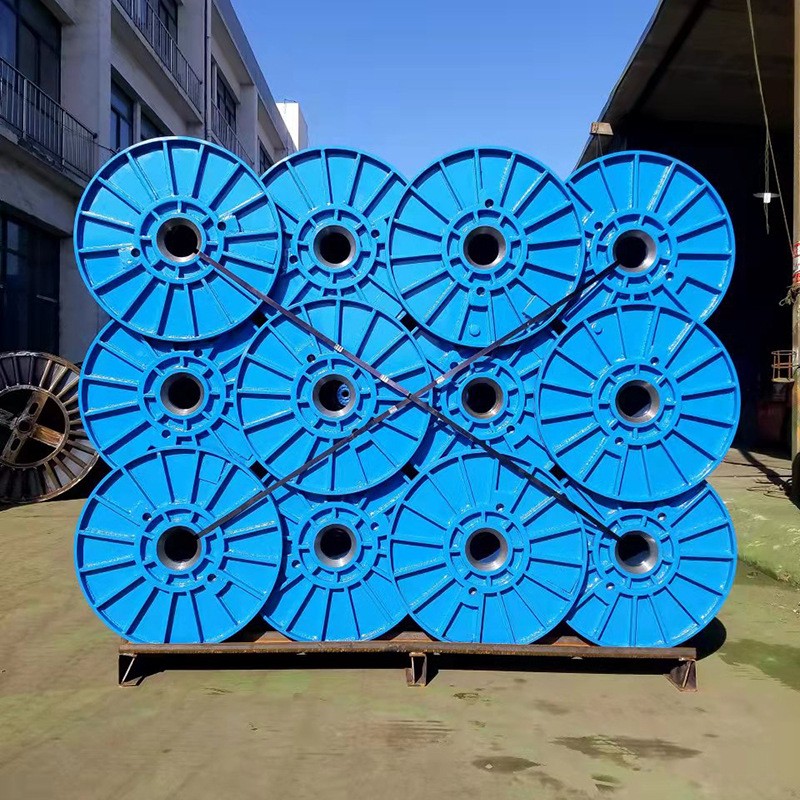

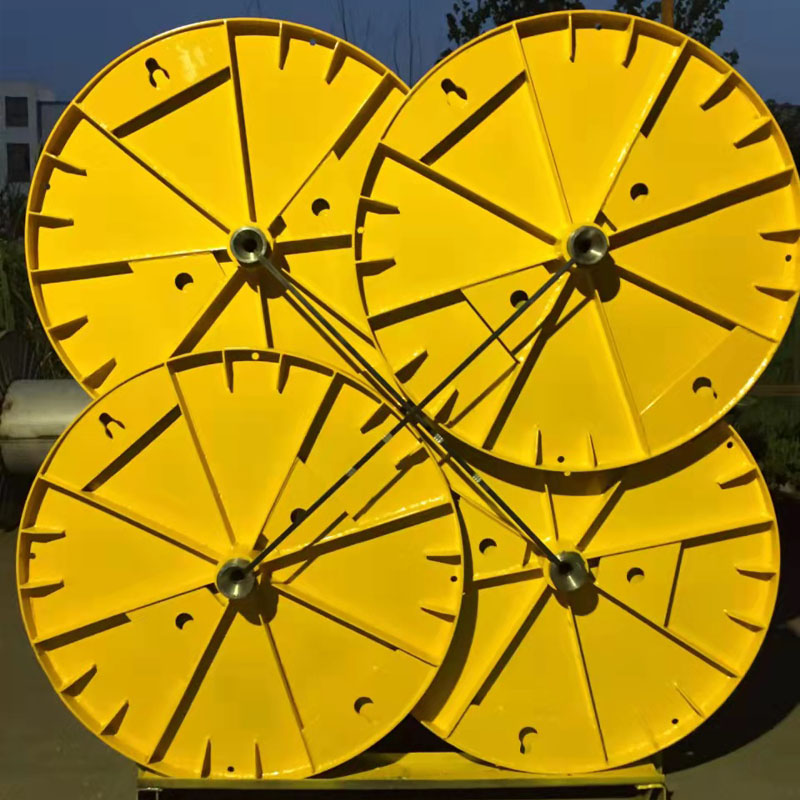

Tightening device for I-shaped wheel take-up and pay-off line

As a large and heavy turnover tool, the I-wheel has been widely used in the metal products industry. The commonly used tightening methods for the retracting and unwinding lines of the I-wheel mainly include screw tightening and pneumatic tightening. Screw tightening is simple and reliable, suitable for applications with relatively low tension requirements. It allows operators to adjust the tension manually by turning the screws, which provides precise control over the line tension and ensures that the metal coils or wires are wound uniformly without slippage.

Pneumatic tightening, on the other hand, uses compressed air to apply consistent and adjustable pressure to the line. This method is particularly advantageous for large-scale or high-speed production lines, as it reduces manual labor, improves efficiency, and ensures stable tension during both the take-up and pay-off processes. Pneumatic systems often include pressure regulators and sensors, allowing real-time monitoring of tension to prevent over-tightening or slack, which could damage the material or affect the quality of the wound product.

In addition to these primary methods, some advanced I-wheel systems incorporate hydraulic tightening or electronic tension control. Hydraulic tightening provides even greater force and is used for very heavy or wide metal sheets, while electronic tension control systems integrate sensors, motors, and feedback loops to automatically adjust tension according to material type, thickness, and line speed. This automation ensures high precision, reduces waste, and increases overall productivity.

Regular inspection and maintenance of the tightening device are essential for long-term performance. Components such as screws, air cylinders, valves, and sensors should be checked periodically for wear, corrosion, or leaks. Lubrication, cleaning, and timely replacement of worn parts help maintain consistent tension and prevent production interruptions.

Overall, selecting the appropriate tightening method for the I-shaped wheel, combined with proper monitoring and maintenance, ensures smooth operation, protects the material from damage, and enhances the efficiency and reliability of metal processing lines.

Related suggestion